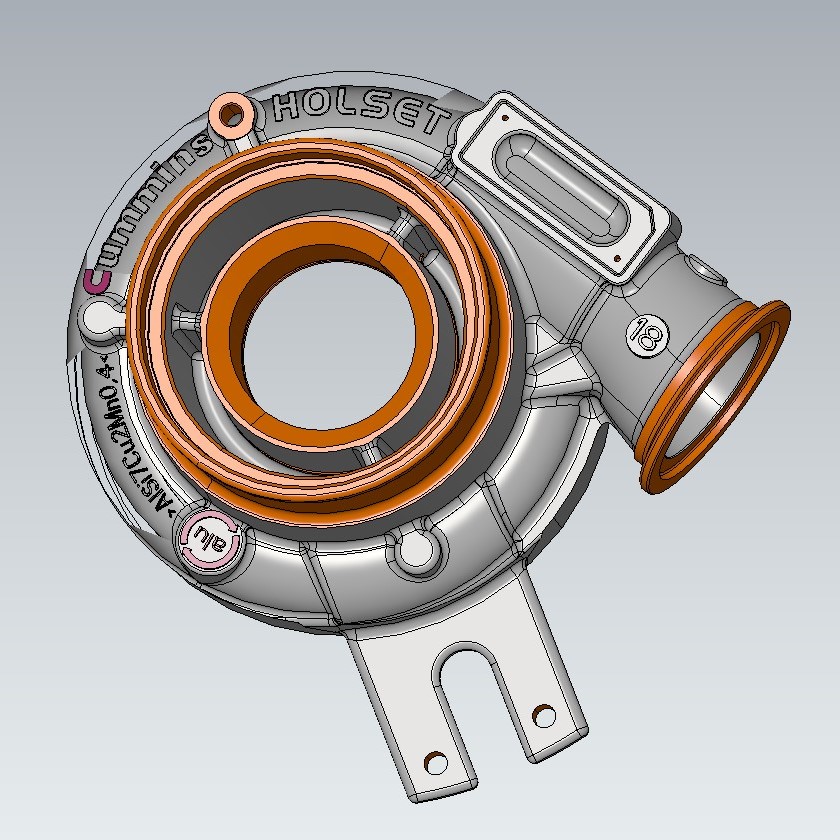

Compressor Housing

Compressor Housing

We are AUTOLUMIN DYNAMIC METALLURGICALS, a dependable name in the automotive manufacturing industry today. We “speak turbo”. We manufacture ready-to-assemble Turbo Compressor Housings of the highest grade.

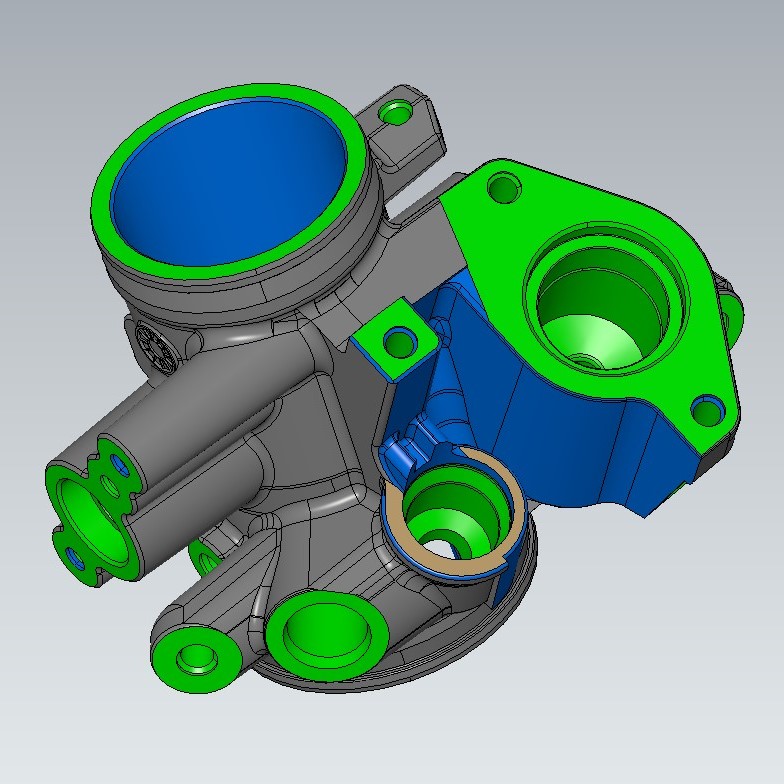

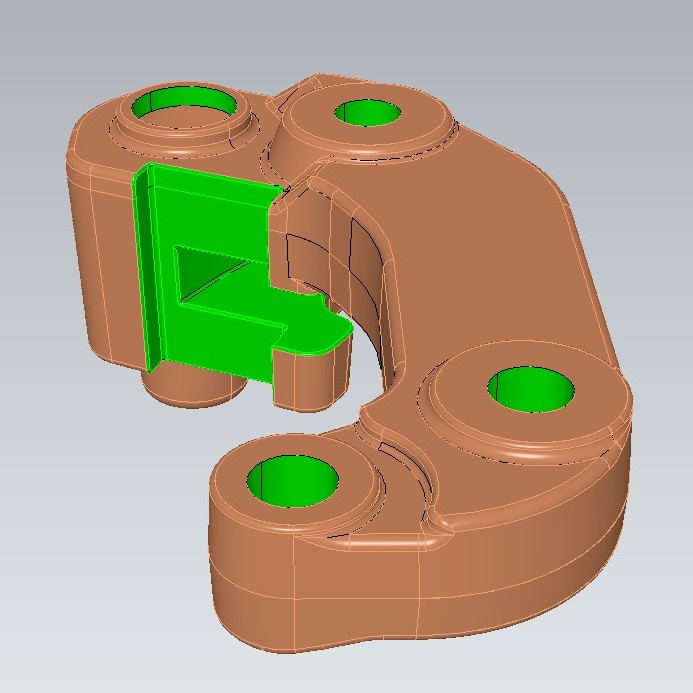

Turbo compressor, by definition, is where clean air is gathered and compressed before entering the engine. It houses the compressor wheel which rotates about a central axis as per which the rotationally symmetric housing is arranged too. With our state-of-the-art manufacturing unit and advanced capabilities, we are well versed with the different anatomies of turbo compressor housings. The efficiency of the compressor is very dependent upon the remaining gap width along the curvature of the cover, thus, requiring a precise adaptation of the wall of the compressor housing to the rotationally symmetrical contour of the compressor wheel. Hence, we always remember the criticality of design and quality.

The production of the compressor covers is critical. We, at Autolumin Dynamic Metallurgicals, use high grade aluminium for turbo housing manufacturing. Turbocharger turbine housings must endure exhaust gas high temperatures ranging and high thermal stresses up.

Turbo Compressor Housing Manufacturer

As an established Turbo compressor housing manufacturer, we ensure that our Aluminum turbo housing manufacturing is lightweight, ready to assemble and free of debris/swarf that can contaminate the oil and cause turbocharger failure. Through our prototyping and technical consultations, we, as the Turbo compressor housing manufacturers make sure to maximize the potential of the OEM spec. Unwanted heat and packaging complexity are always kept in mind when designing, ensuring complete customer and application spec satisfaction. We work through the spec to minimize any possibility of failure in the design process ensuring no porosity issues that can stop your wheels from turning in the long run.