Amwerk values

Engineering the

best solutions

Uniquely enable accurate supply chains rather than frictionless technology. Globally network focused materials vis-a-vis cost effective manufactured products.

Pre-Production Phase

Aimed at providing complete solutions from a single source, Autolumin Dynamic Metallurgicals is here for all critical automotive die-cast product needs and applications.

Prototyping

At the helm of our advanced capabilities is prototyping. Prototype manufacturing (R&D) enables verification of functionality and design intent before tooling and production costs.

Great cast products with high mechanical qualities start with great tooling. This is why before taking a leap into mass production, we take a step back and work on simulation and prototyping. We use computerized flow simulation processes to mimic mold flow to ensure we create the perfect tooling design process with valuable simulations of mold performance. During our prototyping process, batch quantities of prototype parts with material characteristics and accuracy representative of production die casting are produced to provide us a representation of the most accurate mechanical qualities.

Great cast products with high mechanical qualities start with great tooling. This is why before taking a leap into mass production, we take a step back and work on simulation and prototyping. We use computerized flow simulation processes to mimic mold flow to ensure we create the perfect tooling design process with valuable simulations of mold performance. During our prototyping process, batch quantities of prototype parts with material characteristics and accuracy representative of production die casting are produced to provide us a representation of the most accurate mechanical qualities.

Foundry Engineering

Next up, our foundry engineering experts get to work. They kick-off the APQP process in a technically consultative format, working closely with the customer.

We ensure customer and end-application success through our comprehensive Advanced Product Quality Planning process. Our cross-functional, diverse team led by foundry experts engage in multiple technical discussions with the customer as they lay everything out pre-production. In our consultative format, we start determining everything from our tooling, patterns, molds to processes. Within this process, we try our best to further improve the provided design. We utilize all our tools and methods for mitigating the risks associated with mass production of the new product or process.

We ensure customer and end-application success through our comprehensive Advanced Product Quality Planning process. Our cross-functional, diverse team led by foundry experts engage in multiple technical discussions with the customer as they lay everything out pre-production. In our consultative format, we start determining everything from our tooling, patterns, molds to processes. Within this process, we try our best to further improve the provided design. We utilize all our tools and methods for mitigating the risks associated with mass production of the new product or process.

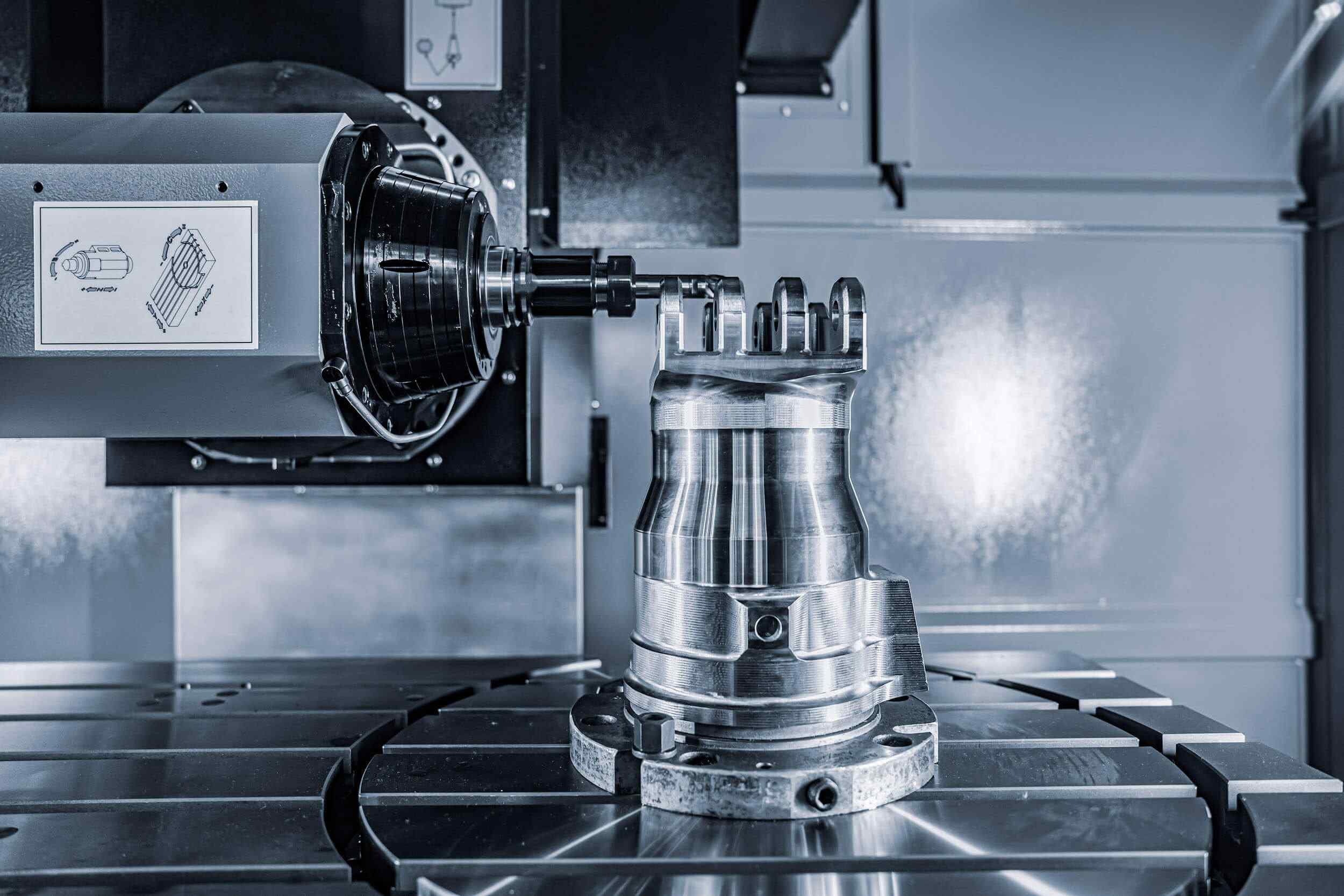

Machine Shop Engineering

Our machine shop tooling kicks off the tooling process.

We understand your needs. Be it a simple cast or a complex geometry with tight tolerances, we have a solution. Already having passed through the prototyping

process, we are ready to produce tooling. Our commitment is highlighted as we are ready to produce a permanent mold at a premature state of the process. The need is for quality built dies which efficiently cope with high volume production with zero down time. Using CAD/CAM designed, precisely machined toolings after performing predictive wear analysis to promote the longevity, we are ready.

We understand your needs. Be it a simple cast or a complex geometry with tight tolerances, we have a solution. Already having passed through the prototyping

process, we are ready to produce tooling. Our commitment is highlighted as we are ready to produce a permanent mold at a premature state of the process. The need is for quality built dies which efficiently cope with high volume production with zero down time. Using CAD/CAM designed, precisely machined toolings after performing predictive wear analysis to promote the longevity, we are ready.

Quality Assurance

Our quality engineering makes sure there is a holistic quality assessment through our Quality Management System (QMS) before we PPAP for serial production.

For that smooth production start-up, we always have a solid plan in place. As we have laid the groundwork so far and are close to the production stage, we lay out the quality control plan. This includes everything from standard production work, machines and equipment, dimensional variations, measurement methods, control methods and reactive plans. We go the next step to create a preventive maintenance plan so we are always running for you.

For that smooth production start-up, we always have a solid plan in place. As we have laid the groundwork so far and are close to the production stage, we lay out the quality control plan. This includes everything from standard production work, machines and equipment, dimensional variations, measurement methods, control methods and reactive plans. We go the next step to create a preventive maintenance plan so we are always running for you.

Choose your solutions Payment plans Payment

Actual Manufacturing Process

Beyond laying the groundwork for your success, our serial production capabilities are automated and computerized including controlled build processes that are subject to high technological and quality standards

Casting

Taking the dimensional stability and mechanical capabilities of Aluminium to our advantage, we are almost ready to mass produce quality automotive components.

Before we start the mass production of your Aluminium cast product, we start the metal prep. Pursuing continual superior foundry metallurgical expertise, our dedicated, on-site metallurgical lab is the first stop. As part of our commitment to quality control, we are incessantly analyzing our pouring metal’s mechanical properties, compositions and alloys. We strive to achieve the chemical specifications the customer needs.

As we ready the metal in our furnace, our instrumentation keeps temperature at a constant level, intrinsically important to ensure efficient pouring and integrity of cast finished goods.

A robot arm accurately pours the cast with calculated precision, no turbulence, and the perfect pouring rate to create good finish and reduced post processes such as fettling.

Before we start the mass production of your Aluminium cast product, we start the metal prep. Pursuing continual superior foundry metallurgical expertise, our dedicated, on-site metallurgical lab is the first stop. As part of our commitment to quality control, we are incessantly analyzing our pouring metal’s mechanical properties, compositions and alloys. We strive to achieve the chemical specifications the customer needs.

As we ready the metal in our furnace, our instrumentation keeps temperature at a constant level, intrinsically important to ensure efficient pouring and integrity of cast finished goods.

A robot arm accurately pours the cast with calculated precision, no turbulence, and the perfect pouring rate to create good finish and reduced post processes such as fettling.

Machining

With our advanced capabilities of CNC turning, vertical milling, boring, drilling, threading and precise machining, we can provide the highest quality finished machined castings. All machining is done with hydraulic fixtures or special chucks for turning. All our cutting tools are sourced from dedicated, reliable sources and suppliers. Our base of suppliers also help with outsourced coating and painting.We also hold the capacity for post-processing like leak tests, washing, and special testing, all is in-house.

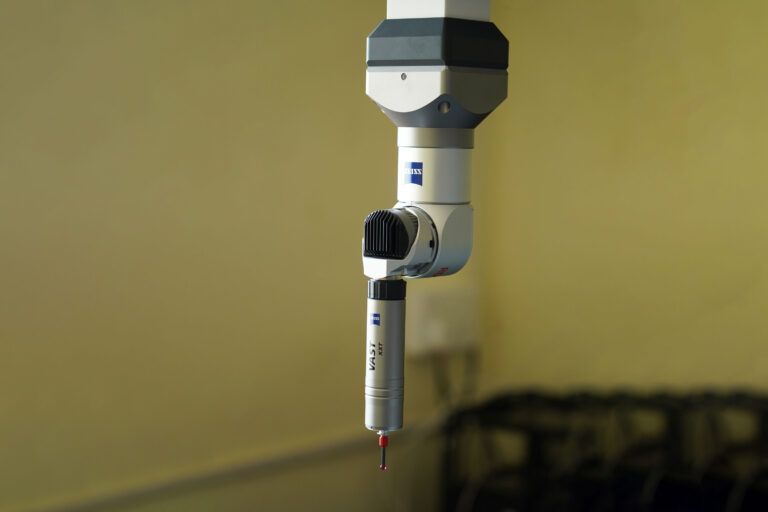

Inspection & Testing

Our metallurgy lab is equipped and ready to receive the cast component. With a variety of tests on batches, we ensure superior quality with Spectrometer, hardness testing and tensile strength testing. Our product’s superior dimensional quality is ensured by CMM testing and complex cast parts are also scanned with our 3D scanning metrology equipment before dispatch.

Casting

Taking the dimensional stability and mechanical capabilities of Aluminium to our advantage, we are almost ready to mass produce quality automotive components.

Before we start the mass production of your Aluminium cast product, we start the metal prep. Pursuing continual superior foundry metallurgical expertise, our dedicated, on-site metallurgical lab is the first stop. As part of our commitment to quality control, we are incessantly analyzing our pouring metal’s mechanical properties, compositions and alloys. We strive to achieve the chemical specifications the customer needs.

As we ready the metal in our furnace, our instrumentation keeps temperature at a constant level, intrinsically important to ensure efficient pouring and integrity of cast finished goods.

A robot arm accurately pours the cast with calculated precision, no turbulence, and the perfect pouring rate to create good finish and reduced post processes such as fettling.

Before we start the mass production of your Aluminium cast product, we start the metal prep. Pursuing continual superior foundry metallurgical expertise, our dedicated, on-site metallurgical lab is the first stop. As part of our commitment to quality control, we are incessantly analyzing our pouring metal’s mechanical properties, compositions and alloys. We strive to achieve the chemical specifications the customer needs.

As we ready the metal in our furnace, our instrumentation keeps temperature at a constant level, intrinsically important to ensure efficient pouring and integrity of cast finished goods.

A robot arm accurately pours the cast with calculated precision, no turbulence, and the perfect pouring rate to create good finish and reduced post processes such as fettling.

Machining

With our advanced capabilities of CNC turning, vertical milling, boring, drilling, threading and precise machining, we can provide the highest quality finished machined castings. All machining is done with hydraulic fixtures or special chucks for turning. All our cutting tools are sourced from dedicated, reliable sources and suppliers. Our base of suppliers also help with outsourced coating and painting.We also hold the capacity for post-processing like leak tests, washing, and special testing, all is in-house.

Inspection & Testing

Our metallurgy lab is equipped and ready to receive the cast component. With a variety of tests on batches, we ensure superior quality with Spectrometer, hardness testing and tensile strength testing. Our product’s superior dimensional quality is ensured by CMM testing and complex cast parts are also scanned with our 3D scanning metrology equipment before dispatch.